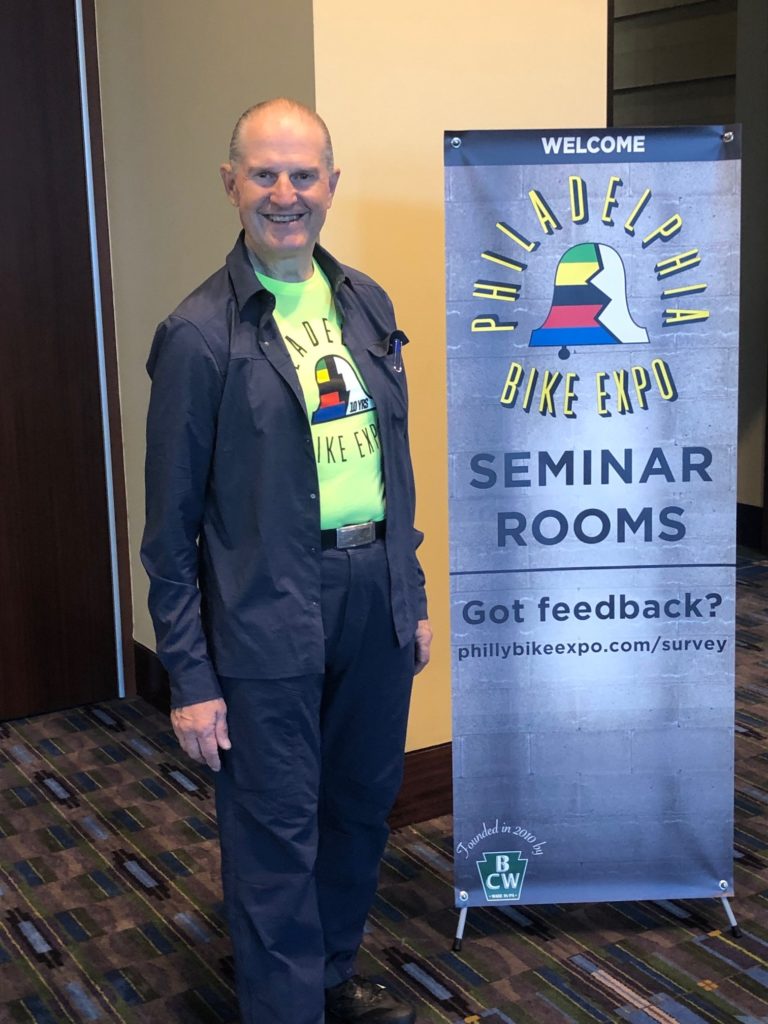

PBE 2026

Vintage Bike Display

Saturday, March 14th 10:00AM – 5:00PM & Sunday, March 15th 10:00AM-4:00PM The Philly Bike Expo will once again feature a collection of vintage lightweight bicycles provided by leading vintage bicycle collectors and dealers. The display is carefully curated by Michael Kone of Classic Bicycles Auburn to show off both ultra rare exotics as well as […]

Ride to the Expo with the Philly Charity Bike Rides

Saturday, March 14th Meeting at Broad and Race streets at 8:00 am we will be rolling out at 8:15 for a 15 ish mile ride showing off some beautiful and iconic scenes of Philadelphia. We will have multiple leaders and all paces are welcome. This is a road ride so all bikes and all abilities […]

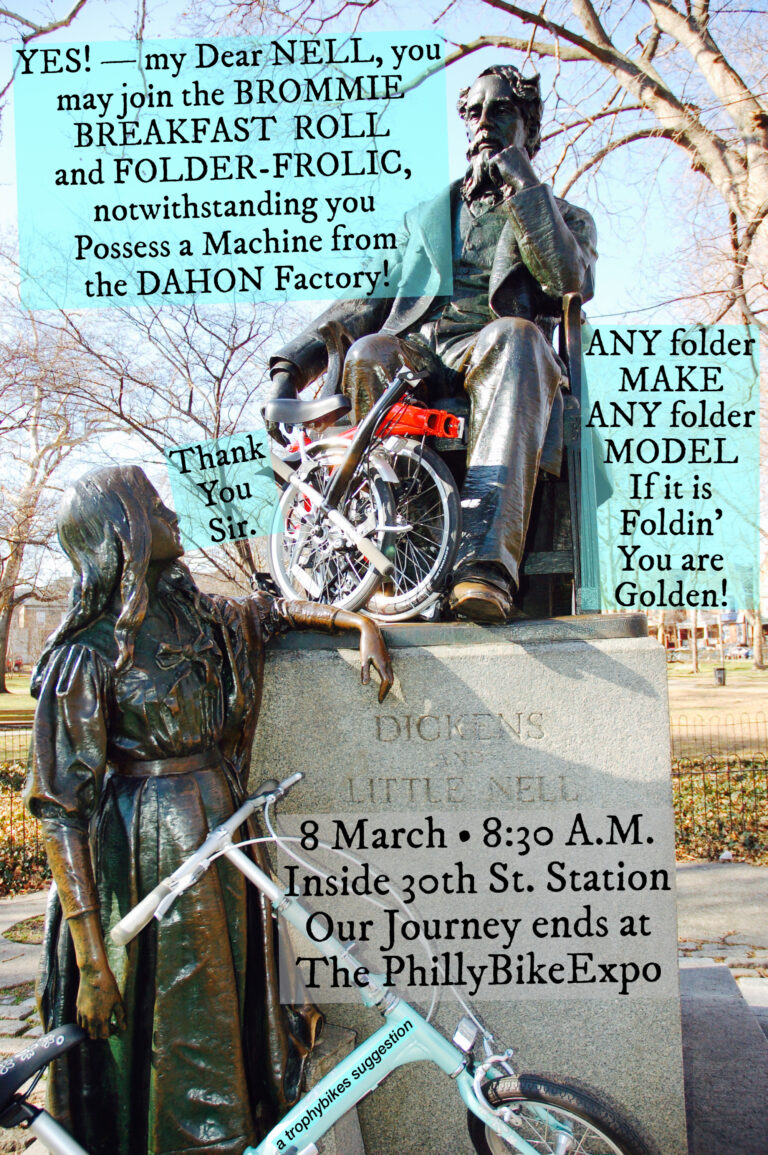

The Ninth Annual BROMMIE BREAKFAST ROLL + FOLDER FROLIC RIDES AGAIN!

Saturday, March 14th, 8:30AM. Meet at Center Info Booth inside 30th Street Station, 30th + Market St. ROLLS ( Party Pace ) at 9 AM and aim to reach the PHILLY BIKE EXPO right around doors open time. Be on time so you get in the CANDID GROUP GLAMOUR PHOTO. YES, scads of BROMPTONS predicted, but […]

Schwinn History – The Story Behind the Story

Saturday March 14th, 12:00 PM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Presented by Richard Schwinn Over a century after Schwinn’s founding, it remains the number one name in the world of bicycles in America. For much of this time, it has operated in relative secret. Now you can learn the […]

Why Harrisburg Matters to Road Safety

Saturday March 14th, 3:00 PM Seminar room: 109A (Ground Level – 12th & Arch Streets entrance) Presented by Piscitello Law and PA Safe Roads PAC In this seminar, Piscitello Law will introduce our cycling community to a key partner in change – the PA Safe Roads Political Action Committee (PAC). We discuss why the PAC […]

The Science of Corrosion for Bike People

Saturday March 14th, 10:30 AM Seminar room: 110A/B (Ground Level – 12th & Arch Streets entrance) Presented by Keithen Orson An introduction to the science of corrosion and why it matters for your bicycle. Common bike maintenance issues like stuck seatposts and rusty chains are discussed with an eye towards understanding different types of corrosion […]

10 Things to Help you Bike More

Saturday March 14th, 10:30 AM Seminar room: 109A (Ground Level – 12th & Arch Streets entrance) Presented by Pamela Murray Every day can be a bike adventure when you’re well-equipped. Ride from home to your next bike adventure. Find out 10 things that help me to bike daily.

CyclingSavvy Ride to PBE – 2026 Edition

Sunday, March 15th Meet at 7:45 am at the Convention Center/Roll at 8:00 am (12th & Arch Streets entrance, across from the Reading Terminal Market) Come see the sights of Philly with CyclingSavvy Instructors demonstrating a few of our strategies and techniques. Part sightseeing, part CyclingSavvy demonstration ride. Building your situational awareness using CyclingSavvy skills […]

International Women’s Day 107K

Saturday March 14, 8:00AM (Registration required) Join the Pennsylvania Randonneurs for a welcoming populaire that rolls out from Philadelphia, follows quiet suburban roads to Evansburg State Park, and returns to the Expo. Randonneuring events are unsupported, self-paced, and non-competitive, with camaraderie very much at the heart of the rides. Expect to see a wide range […]

Jamaica: Pedalling through Reggae Paradise – Part 2

Saturday March 14th, 1:30 PM Seminar room: 110A/B (Ground Level – 12th & Arch Streets entrance) Presented by the Jamaica Tourist Board Whether it be mountain, paved road, gravel, triathlon, leisure or competitive… any kind of cycling in Jamaica is done with a reggae beat. Join the Jamaica Tourist Board team and Jamaica National Cycling […]

Crank Length: The long and Short of It

Sunday March 15th, 12:00 PM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Presented by Matt Appleman, Appleman Bicycles, Crank Length Enthusiast Crank length is super weird. The potential to increase speed and comfort by changing crank length is huge! Let’s take a look at the mystical and magical creature of crank […]

Learning the 911 Trail

Sunday March 15th, 3:00 PM Seminar room: 109A (Ground Level – 12th & Arch Streets entrance) Presented by Jeffrey McCauley- President of the September of the September 11th National Memorial Trail Alliance, Bruce White – Ride Director htcdigtree@aol.com Come and learn about the federally designated 911 Trail and a way to honor the heroes of […]

Bikepacking by Transit from Philadelphia

Sunday March 15th, 1:30 PM Seminar room: 110A/B (Ground Level – 12th & Arch Streets entrance) Presented by Julian Bender, The Jersey Devil Hunt Want to go bikepacking from Philadelphia, but don’t want to deal with cars? Our regional train network offers lots of options for access to bikepacking destinations near and far! Come to […]

Find a gravel event in Pennsylvania that’s right for you.

Saturday March 14th, 1:30 PM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Looking for a great gravel event to ride or race this year? Pennsylvania has plenty to choose from and 11 event directors are ready to tell you about them—speed dating style! Dave Pryor, Monkey Knife Fight, Grinduro, PA Gravel […]

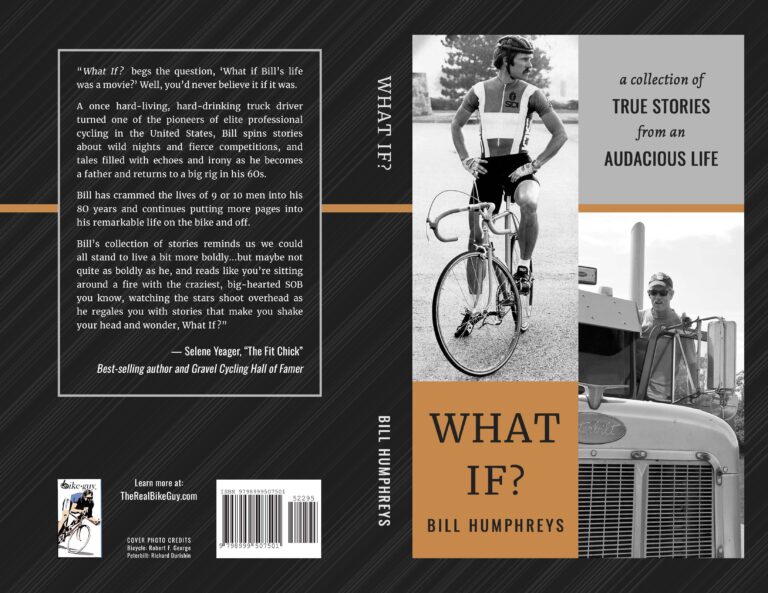

What If?

Sunday March 15th, 12:00 PM Seminar room: 110A/B (Ground Level – 12th & Arch Streets entrance) Presented by Bill Humphreys, Author Best selling cycling book with other adventures and distractions thrown in. This is an inspiring collection of real-life “What If’s,” chronicled by Bill Humphreys in an entertaining booklet. These stories offer readers not only […]

“OVERALLS Route” A Gravel Bike Adventure | 505 Miles

Saturday March 14th, 4:30 PM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Film and Q&A Presented by Jake Haines, Pennsylvania Dirtbags Pennsylvania Erie to Philadelphia | A Gravel Bike Adventurepennsylvania.dirtbags Distance: 505 miElevation: 36.469 ft.5 Days – 4 Nights A band of misfits, commonly known as the Pennsylvania Dirtbags, headed from […]

Cycling Through the Menopause Transition

Saturday March 14th, 3:00 PM Seminar room: 110 A/B (Ground Level – 12th & Arch Streets entrance) Presented by Selene Yeager, Hit Play Not Pause Podcast Hot flashes. Mood swings. Sleepless nights. Joint pain. Body composition changes. Fatigue. And unpredictable performance. During the menopause transition, you never quite know which body will show up on […]

Learn to Ride Strategies for Tweens

Saturday March 14th, 1:30 PM Seminar room: 109 A (Ground Level – 12th & Arch Streets entrance) Presented by Sarah Billington Teaching older kids or tweens to learn to ride a bicycle (ages 9+ to 16) comes with some unique challenges that either child or adult curriculum are not well adapted. Focus areas of this […]

PA’s Endless Gravel & Wild Elk: Storytelling Through Pennsylvania’s Unpaved Backroads

Saturday March 14th, 10:30 AM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Presented by David Landis, V2V Trails Northern Pennsylvania is home to more than 25,000 miles of unpaved roads—and two ambitious projects are bringing them to life. Endless Gravel PA and Wild Elk Gravel PA offer curated route networks of […]

Hill Climbing Tips and Tricks

Saturday March 14th, 12:00 PM Seminar room: 110 A/B (Ground Level – 12th & Arch Streets entrance) Presented by Brian Williams, Major Taylor Techniques to help you ascend those dreaded hills properly, climb efficiently with minimum wasted effort and boost confidence.

Tour of unPAved-Philly

Sunday, March 15th, Meet at the Rocky Steps at 7:50am/Roll at 8:00am Led by unPAved Pennsylvania and PBE Squad – Sponsored by Schwalbe & Stan’s

Ride with Dave & Bobby of the PBE Squad

Saturday March 14th, Meet at the Bala Cynwyd SEPTA train station at 9:00am Join local squad members Dave Kerwood and Bobby Graham for a guided ride to the Philadelphia Bike Expo from the Bala Cynwyd train station. The Bala Cynwyd train station is conveniently located at the top of the Cynwyd Heritage Trail, which we’ll […]

Trusty 20 with T3 Philly Multisport

Sunday March 15th, Meet at the Trellis @10:00am Who: ALL are welcome What: Wake up and ride with local triathlon group T3 Philly, along with our friends at the Philly Bike Expo! We’ll ride the beautiful “Trusty 20” route, starting at the Trellis by the art museum and concluding at the Philly Bike Expo, held […]

Plan B Training and Exercise When Sidelined by Illness or Injury

Sunday March 15th, 1:30 PM Seminar room: 109 A (Ground Level – 12th & Arch Streets entrance) Presented by Linda A. McGrane, MS, OTR/LOccupational Therapist and GerontologistOwner, Bike Tours by Linda, LLC Alternative training & exercise strategies during and after illness or injury, requiring short-term suspension of one’s cycling program during the rehabitation/reconditioning process. Positive […]

Bike Fit Unplugged

Saturday March 14th, 3:00 PM Seminar room: 109B (Ground Level – 12th & Arch Streets entrance) Presented by Happy Freedman, The Center for Bike Fit The science of bike fitting without a computer. Determining the proper positions on a bike through the use of gait evaluation, postural corrections, and exercise recommendations for a more stable, […]

Yoga for Cyclists

Saturday March 14th, 12:00 PM Seminar room: 109A (Ground Level – 12th & Arch Streets entrance) Presented by Ruchama Bilenky, Certified Yoga Instructor and Therapist Bicycling utilizes parts of the body in ways that are different from standing, walking, running, or sitting. With today’s gas prices, more and more people are taking up cycling for […]

PBE 2025

Varlo Running Apparel

Product Review by PBE Squad member, Jennifer Wright Finding the right configuration of running gear is always a gamble – does it chafe? Does it breathe? Does it stay in place? I’ve been running all season in Varlo’s running line and I have answers to all of these questions! A bit about me: – I run […]

RedShift Sports ShockStop Suspension System

Product Review by PBE Squad member, Trong Nguyen As an avid cyclist who regularly tackles everything from gravel paths to limited mountain bike trails, and even rough city potholes (Philly residents would know this), I have always struggled to find the right balance between comfort and control on rough terrain. That is, until I tried the […]

Jamaica: Pedalling through Reggae Paradise

Saturday March 8th, 1:30 PM Seminar room: 125 (Atrium Level) Presented by the Jamaica Tourist Board and Coach Carlton Simmonds Whether it be mountain, paved road, gravel, triathlon, leisure or competitive… any kind of cycling in Jamaica is done with a reggae beat. Join the Jamaica Tourist Board team and Jamaica National Cycling coach Carlton […]

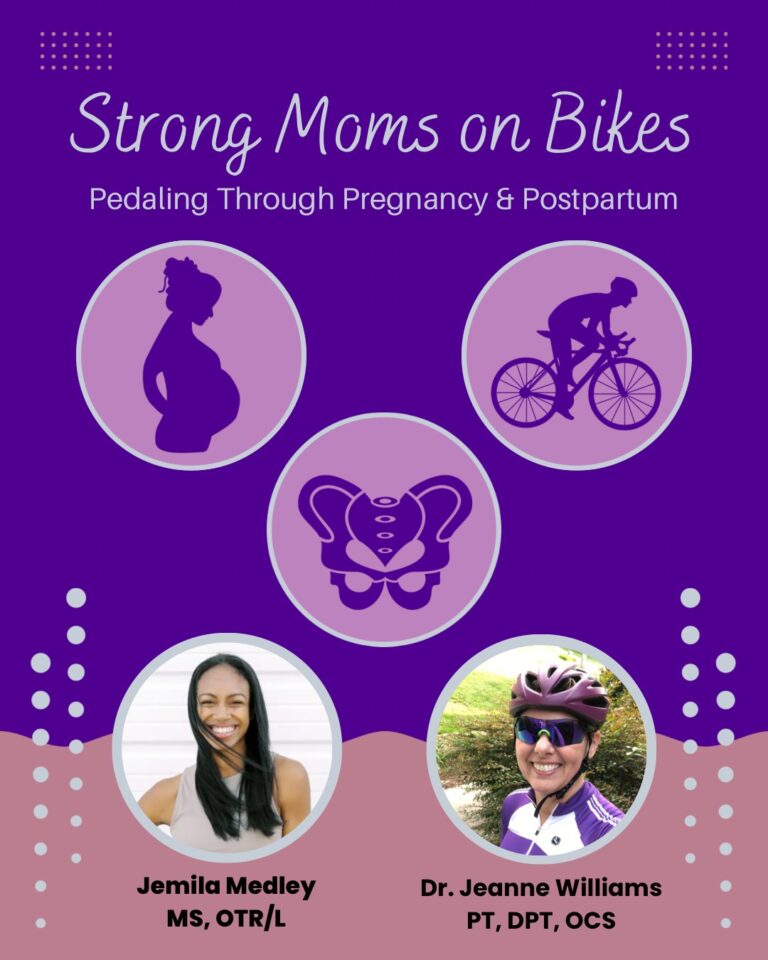

Strong Moms on Bikes: Pedaling Through Pregnancy & Postpartum

Sunday March 9th, 1:30 PM Seminar room: 125 (Atrium Level) Cycling doesn’t have to stop when motherhood begins! Whether you’re a pregnant rider looking to stay active or a postpartum cyclist eager to get back in the saddle, this session is designed to help you navigate the unique challenges of riding before, during and after […]

Philadelphia’s Charity Rides Seminar

Saturday March 8th, 10:30 AM Seminar Room, 124 Join us to hear about how The Foster 100, FBB Ben to the Shore, ACS Bike A Thon and the Eagles Autism Challenge are changing lives for the better everyday. We will go into what makes a charity bike ride special and how impactful it can be for […]

NightCycle PHL

Saturday March 8th, Meet at the Rail Park at 6:00pm, Roll at 6:30pm Led by Cycle Scene PHL Meet at the Rail Park: On Noble Street, between Broad St and 13th Street, half a mile from the Convention Center. Use the address 1309 Noble Street for GPS routing. Our destination: Keystone Bike’s Expo After-Party. Don’t […]

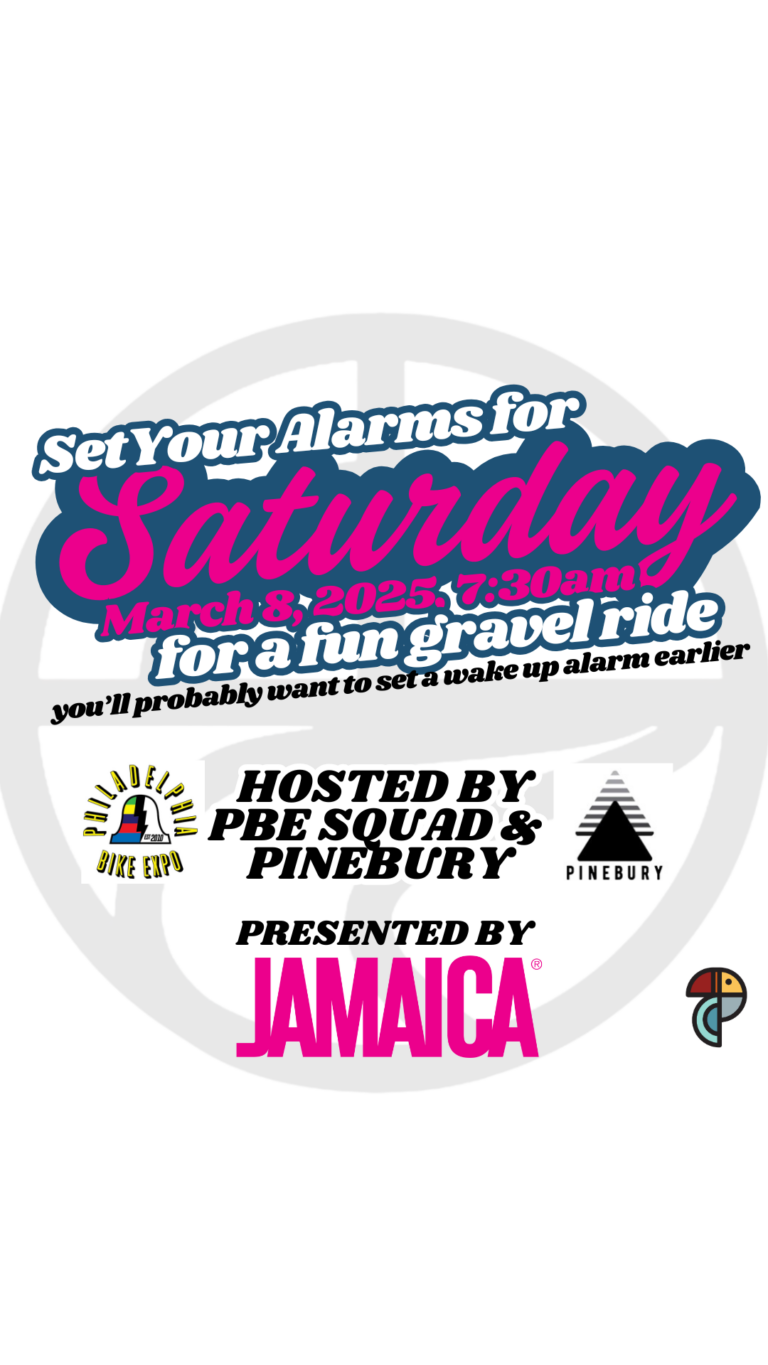

PBE x Pinebury Gravel Ride p/b Jamaica Tourist Board

Saturday March 8th, 7:15 AM 7:15 meetup 7:30 roll Meet at the Art Museum Steps

The Haute Dog Ride

Saturday March 8th, 5:30pm Meet at the Philly Bike Expo bike valet Hosted by Industry Nine + Haute.Bike Route: https://ridewithgps.com/routes/45860443

The Impossible Routes Q&A

Saturday March 8th, 4:30 PM Seminar room: 124 (Atrium Level) Join Jeremiah Bishop 3 time USA National Champion and founder of the Impossible Routes Documentary series on a brief talk about taking on the Impossible! Our limits in life are in many cases self imposed, how do we break thru and take on life’s biggest […]

Planning a Bike Route using Ride with GPS

Sunday March 9th, 3:00 PM Seminar room: 125 (Atrium Level) Presented by Howie Wiener, Bicycle Club of Philadelphia What makes a good bike route? How can bike routes be created and shared with others? A group of experienced route planners from the Bicycle Club of Philadelphia will highlight some the basic considerations when planning a […]

Bridging Body and Bike: Riding Further, Stronger, Better — Is it the body, the bike, or both?

Saturday March 8th, 4:30 PM Seminar room: 123 (Atrium Level) Presented by Dr. Jeanne Williams, PT, DPT, OCS In the world of cycling, performance and comfort are shaped by the harmony between the rider and the machine. When discomfort, inefficiency, or nagging injuries creep in, is the problem the bike, the body, or both? Unlike […]

Randonneuring: The Art of Going Long

Saturday March 8th, 3:00 PM Seminar room: 125 (Atrium Level) Presented by Randonneurs USA Are you looking for a new challenge and aspire to explore and push your boundaries on the bike? Do you like long adventures on the bike? Would you like to join a welcoming, engaged, and adventurous community? Randonneuring is defined as […]

Basic Bike Maintenance

Saturday March 8th & Sunday March 9th, 10:30 AM Exhibit Hall E Demo Area, Booth #1900 Presented by VeloJawn

Laws we need to Make our Roads Safe

Saturday March 8th, 3:00 PM Seminar room: 124 (Atrium Level) Presented by: Joe Piscitello & Marissa Perrone, Piscitello Law Nicole Brunet, Bicycle Coalition of Greater Philadelphia Ayeshia Poole & Jasmine Hoffman: Jay Alert This Seminar focuses on four laws in play for 2025: Join this seminar to get the most current updates and learn how to […]

Bikepacking Roots Presents: Perspectives on Building Community in the Outdoors from BIPOC Leaders

Saturday March 8th, 12:00 PM Seminar room: 125 (Atrium Level) Overview: Join Devin Cowens, connector, community organizer, avid bikepacker and coordinator of the BPR BIPOC Bike Adventure Grant Program in conversation with CJ Goulding, Ariel Marlowe, and Tia Moore, three recent awardees from their previous grant cycle. Panelists will share the work they are doing in […]

How to Bike the D&L Trail–140 Miles of Goodness in Your Backyard

Sunday March 9th, 3:00 PM Seminar room: 123 (Atrium Level) Presented by Robert Ostroy, Jonathan Gray, gravel biking enthusiast and Ed Eppler, marathoner and cycling enthusiast The D&L Trail is more than 140 miles long and begins just 20 miles from downtown Philly. This session will include resources and strategies for biking the trail and […]

How to make your life into one big bike adventure – a workshop

Sunday March 9th, 10:30 AM Seminar room: 124 (Atrium Level) Presented by Pamela Murray Pam will share her experiences of how she has incorporated biking into her life. Every day is an adventure on bike. Whether you’re running errands or traveling by bike. And everything in between. Build the ride you want to ride. In […]

CyclingSavvy Ride to PBE

Sunday, March 9th Meet at 7:45 am at the Convention Center/Roll at 8:00 am (Broad and Cherry Streets entrance, across from the paintbrush) Come see the sights of Philly with CyclingSavvy Instructors demonstrating a few of our strategies and techniques. Part sightseeing, part CyclingSavvy demonstration ride. The same route can be ridden in different ways […]

Party Pace ride to the Keystone Bike Party

Saturday March 8th, Meet at 6:45pm at the Convention Center, roll at 7pm sharp (Broad and Cherry Streets entrance, across from the paintbrush) Led by Pamela Murray, Pam Likes to Bike Join us for a Party Pace ride to the Bike Party at Keystone Bikes. All bikes welcome. Steel, vintage, Alt bar bikes encouraged. Helmet […]

Ride with the Philly Charity Bike Rides

Saturday, March 8th Meeting at Broad and Race streets at 8:00 am we will be rolling out at 8:15 for a 15 ish mile ride showing off some beautiful and iconic scenes of Philadelphia. We will have multiple leaders and all paces are welcome. This is a road ride so all bikes and all abilities […]

Chain Waxing for All Conditions

Saturday March 8th & Sunday March 9th, 1:30 PM Exhibit Hall Demo Area, Booth 1900 Presented by Travis Verhoff – Product Manager – SILCA. Learn how to optimize your chain wax to ensure optimal performance for any event. Chain waxing has so many benefits from drivetrain life, efficiency, and cleanliness that it makes it the […]

THE BROMMIE BREAKFAST ROLL

+ FOLDER FROLIC (A “Brompton + Beyond” Ride*) *ALL FOLDERS WELCOME • ANY MAKE, ANY MODEL “If it’s FOLDIN’, You’re GOLDEN.” SAT. March 8, 8:30 a.m. Center Info Booth inside 30th Street Station, 30th + Market St. (optional) RAMP CLIMB + (required) Group Fold Foto. ENDS at the Philly Bike Expo, just about opening time. […]

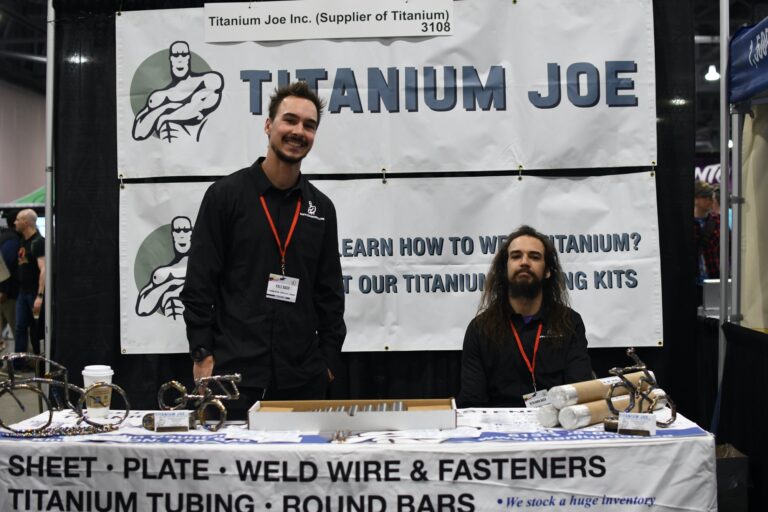

Titanium – A Deep Dive with BinghamBUILT

Saturday March 8th, 4:30 PM Seminar room: 125 (Atrium Level) Presented by Brad Bingham, BinghamBUILT A brief history of Titanium as a high tech material for many applications with an emphasis on bicycle frame construction followed up with alloy and process selections for bicycle frame construction including machining and welding.

Training, Performance & the Menopause Transition: What Do Hormones Have to Do with It?

Sunday March 9th, 12:00 PM Seminar room: 125 (Atrium Level) Presented by Selene Yeager Perimenopause and menopause hit active women differently. We have a different lifestyle and different goals. And we know our bodies. Whether you race, ride for fun, bikepack, tour (or a little of everything!), you’ve had a way of eating and exercising […]

Pedaling Into Community: Engaging Locally on Bikepacking Journeys

Saturday March 8th, 3:00 PM Seminar room: 123 (Atrium Level) Presented by David Landis, V2V Trails Bikepacking isn’t just about ticking routes off a bucket list—it’s about connecting with the people, stories, and culture that make each place special. This session invites cyclists to go beyond the map, discovering how local communities shape the routes […]

Trading Silver-Braze for Sawdust

Sunday March 9th, 10:30 AM Seminar room: 123 (Atrium Level) Presented by Jay Kinsinger, Sojourn Cyclery BMX was in its infancy in 1973. My friends and I were early adopters. I traded labor at a local bike shop for parts to convert my Schwinn Stingray into a BMX bike. I was eventually employed at the […]

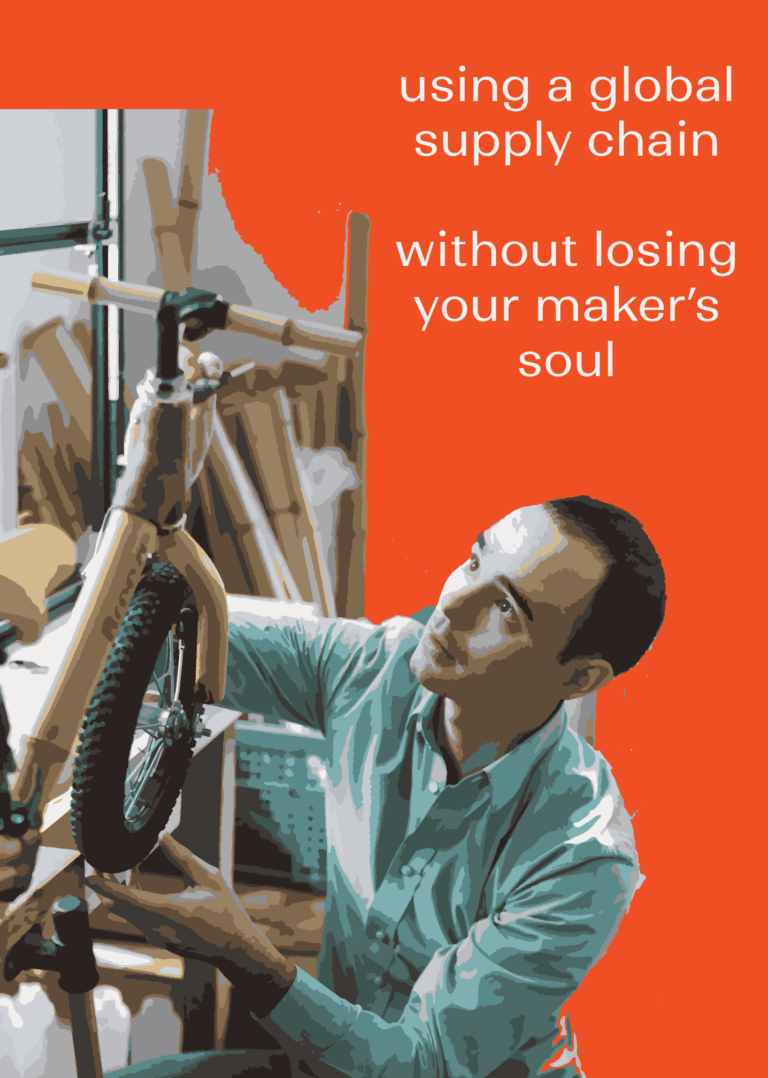

Micro Manufacturing: Taking Advantage of International Supply Chain without Losing your Soul

Sunday March 9th, 12:00 PM Seminar room: 124 (Atrium Level) Presented by David Wang, Brook & Breeze founder Over the past 10 years, David Wang has been designing and fabricating bikes and bike stuff using his hands, power tools, and desktop digital fabrication equipment (i.e. lasers and 3d printing). There’s A LOT of joy in […]

Grassroots Bicycle Advocacy in Philadelphia

Saturday March 8th, 10:30 AM Seminar Room, 125 Presented by Caleb Holtmeyer, Philly Bike Action This seminar is about grassroots advocacy for better bike infrastructure in the City of Philadelphia. We will discuss what good bike infrastructure looks like, how our organization works at the hyperlocal level to speed its implementation, and how you can […]

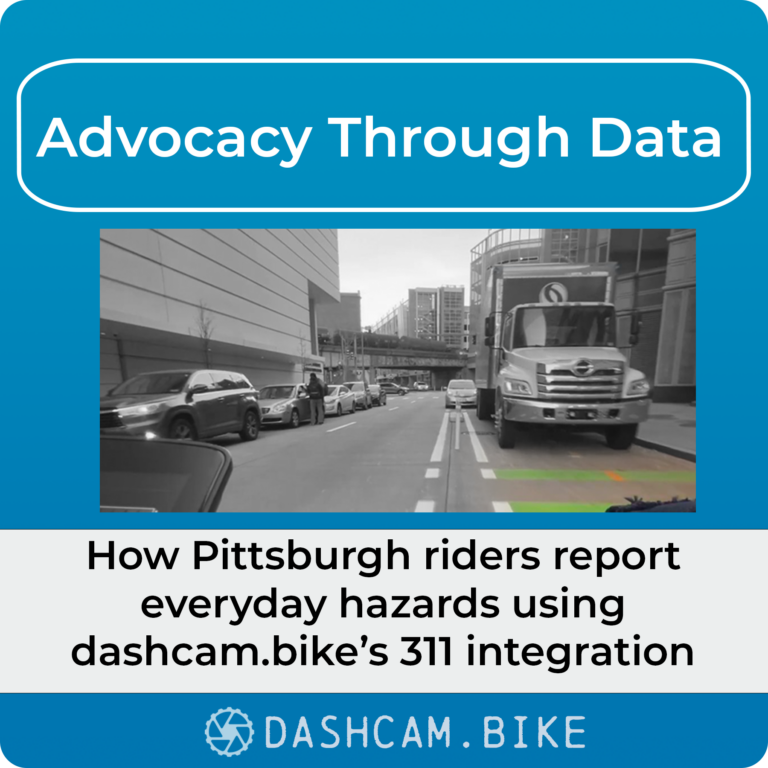

Advocacy Through Data: How Pittsburgh is using 311 data to improve bicycling safety

Saturday March 8th, 1:30 PM Seminar room: 123 (Atrium Level) Armin Samii, dashcam.bike Riders in Pittsburgh have reported thousands of bicycling hazards to 311, including cars parked in bike lanes, near-misses, close-calls, and dangerous road conditions. Riders record video footage of their entire commute using dashcam.bike, and when they’re safely at their destination, they can […]

Vendor Bender at VeloJawn

Friday March 7th, 6:00 PM 3946 Lancaster Ave., Philadelphia, PA 19104 Doors open at 6:00pm Food & Beverage Available Vegan Options Available Happy Hour All Philly Bike Expo exhibitors & attendees are invited! Tickets available here.

How much of a cyclist’s power (Watts) is associated with frame flex while pedaling?

Sunday March 9th, 12:00 PM Seminar room: 123 (Atrium Level) Presented by Bob Rose Is there a meaningful ‘power penalty’ associated with a more flexible frame? After quantifying such power penalty (i.e., Watts of power loss) we will body slam “vertically compliant, laterally stiff” once and for all, then take a deep dive into frame […]

Safety First Cycling & Riding in Groups

Sunday March 9th, 1:30 PM Seminar room: 124 (Atrium Level) Presented by George Yarnell, Bicycle Club of Philadelphia Putting “Safety First!” when cycling should be a matter of habit for all cyclists. This seminar highlights some of the important and basic things we can each do to cycle more safely. Through presentations and demonstrations from […]

The Fastest Bicycle Rider in the World

Sunday March 9th, 10:30 AM Seminar room: 125 (Atrium Level) Presented by Cyrille Vincent More than a hundred years ago, when bicycle races drew crowds that filled Madison Square Garden, the biggest draw of all was Marshall W. Major Taylor. As a superstar athlete in the most popular sport of his era, 1899 world bicycling […]

The Jersey Devil Hunt: Bikepacking in the New Jersey Pine Barrens

Saturday March 8th, 1:30 PM Seminar room: 124 (Atrium Level) Presented by Julian Bender The Pine Barrens is a sprawling wilderness right in Philadelphia’s back yard. Last year, I created the region’s first bikepacking route, the Jersey Devil Hunt. The route makes it easy to discover these vast woods, avoiding all the deep sand and […]

Hill Climbing Tips and Tricks

Saturday March 8th, 12:00 PM Seminar room: 124 (Atrium Level) Presented by Brian Williams, Major Taylor Techniques to help you ascend those dreaded hills properly, climb efficiently with minimum wasted effort and boost confidence.

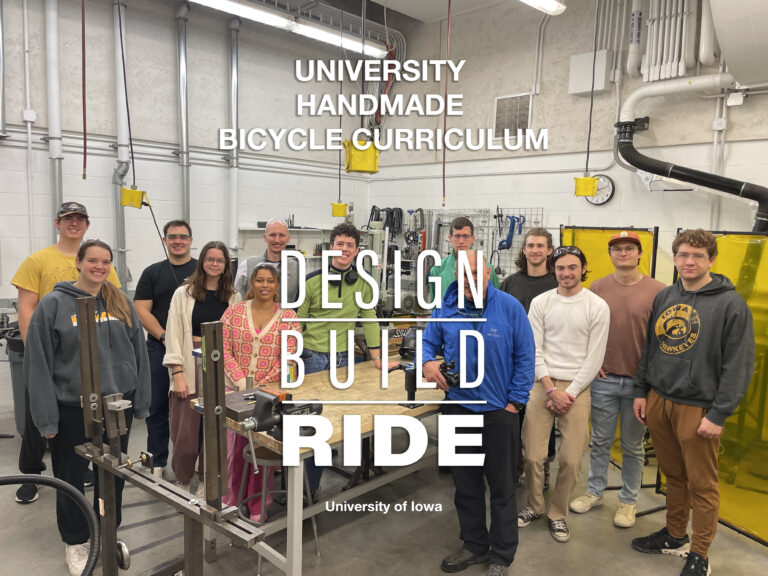

University Handmade Bicycle Curriculum

Saturday March 8th, 10:30 AM Seminar room: 123 (Atrium Level) Presented by Steve McGuire, Professor Over the last 13 years, the Design, Build, Ride curriculum – part of 3D Design and Jewelry and Metal Arts – in the School of Art, Art History & Design at the University of Iowa has become a top handmade […]

PBE 2024

Varlo Running Apparel

Product Review by PBE Squad member, Jennifer Wright Finding the right configuration of running gear is always a gamble – does it chafe? Does it breathe? Does it stay in place? I’ve been running all season in Varlo’s running line and I have answers to all of these questions! A bit about me: – I run […]

RedShift Sports ShockStop Suspension System

Product Review by PBE Squad member, Trong Nguyen As an avid cyclist who regularly tackles everything from gravel paths to limited mountain bike trails, and even rough city potholes (Philly residents would know this), I have always struggled to find the right balance between comfort and control on rough terrain. That is, until I tried the […]

Philly Expo Squad Built ATRB (All Terrain “Road” Bike)

Product Review by PBE Squad member, Shane Sellers As a new member of the Philly Bike Expo Squad, I wanted to build a bike that was a new direction for me. A bike that can do it all is never the answer and always the answer. My 2023 objective was to use specific parts on a bike […]

Varlo Gravel Bib

Product Review by PBE Squad member, Dave Kerwood Cycling is great because you can explore the sport how you wish – simply hopping on your bicycle and riding, or by utilizing the latest and greatest gear and tools to make your adventure-by-bike more comfortable, or even faster. I am a believer that technical clothing will […]

Redshift Sports Kitchen Sink Gravel Handlebar System

Product Review by PBE Squad member, Ross Perfetti I was new to the wide drop-bar trend for gravel bikes before I came across the kitchen sink gravel bars. While narrower bars for road bikes purport greater efficiency and speed, wider, flared drop bars can enhance handling on rougher terrain, from gravel to trail and single-track […]

Redshift Sports Arclight Pro Flat Pedals

Product Review by PBE Squad member, Katelyn Repash It can be tough to feel visible enough on the road or on the trails, which is why I really wanted to try out Redshift’s Arclight flat pedals this year. I’ve been testing out the Pro Flat pedals on road and gravel, in dark and lowlight conditions […]

Schwalbe Pro One

Product Review by PBE Squad member, Gabe Markowitz Tires are the only contact point between your bike and the ground you’re rolling on. Why settle for anything less than great? Schwalbe continued to keep the Philly Bike Expo Squad rolling smooth for the 2025 season. I’ve been running the Pro One Tubeless (700x28c) on my […]

Extended Adventures: Bilenky Gravel eBike

Bilenky Cycle Works stands among the select few bespoke frame builders ready and willing to craft ebikes, a fact starkly evident at the Philly Bike Expo where Steve Bilenky’s enterprise stood as a beacon amidst a sea of – albeit excellent – custom built convention. The reticence of many frame artisans toward embracing ebike technology […]

2016 -> Now: A history of Shrimpy’s racing career with the Philly Bike Expo

Hellloooo Philly Bike Expo Friends! If you have been around for a while, you likely watched this story unfold over the last handful of years. If you are new to the Philly Bike Expo family, I would love to share with you the story of how the Bilenky’s took me under their wing and helped […]

Fine Bikes, Fine Times

You move to a new city for work, you get swept up by the enthusiasm and excitement of the cycling community there, so you leave your job, start working in a bike shop and then become a frame builder. Happens all the time, right? Not! That’s what happened to Charles Thompson after moving to Raleigh, […]

Deep Custom Carbon

What did you do during the Covid shutdown of 2020? For Ben Jurgensen, then a 33 year-old sculpture studio teacher at the Rhode Island School of Design, the conditions were suddenly right to set out on the path of bicycle frame building, “my sourdough,” as he describes it. Ben set himself the problem of finding […]

Zabrina Cycles: When Less is More

One of the great things about the frame builder industry is the steady inflow of energetic young, clever people that continues show up and set up for the long haul. Zach Weiss is all of the above, and he’s gone about it in a time-honored fashion, apprenticing under a highly respected frame builder, in this […]

A New Line of Japanese Titanium

Frame tubes are among the least-known parts of a bicycle frame to many consumers, yet they greatly affect the way a bike feels and handles, how long it will last, and what it will do in a crash situation. Therefore, as an end-user, it’s always well worth stopping at tubing supplier booths at the Philly […]

Tools U Like

What’s one mistake home mechanics make all too often? Neglecting to invest in a good work stand. So when Efficient Velo Tools, which is based in Washougal, Washington, announced they’d partnered with Japanese manufacturer Minoura on an expert-level workshop stand that’s easily adaptable to field work, we were excited that this would be on the […]

Bike Adventurers in the Keystone State

Located between Norris Square and Fishtown, and founded in 2020, the Keystone Bicycle Company (aka KBC) has had a booth in the Philly Bike Expo every year of its existence, and is recognized for pushing the spread of bike shops into North Philadelphia. With a mission to get more people on bikes through active engagement […]

Chapman: Classic but not Retro

The Rhode Island frame builder is lauded for his classic-style frames, but he welcomes the expansive design approaches and passion of newer entrants to the industry, and the use of new tech in general. His bikes, within their classic overall looks, usually contain some of the latest tech amid an array of appealing design touches.

The Unstoppable Ben Serotta

Build, perfect, repeat and pass it on. That could be the company motto of the Serotta Design Studio. If imitation is the sincerest form of flattery, the legendary framebuilder Ben Serotta must surely feel profoundly flattered. Being imitated is a thing he came to know well as one of the largest and most innovative custom […]

Dogwood Cycleworx: The Best Way to See the World

Ask David Johnson a simple question and you won’t receive a 30-second soundbite answer. What you will receive from the loquacious North Carolina native is a wide-ranging explanation filled with humorous anecdotes, intensive technical knowledge, and, in Johnson’s own words, experience borne from “forty years of pain and suffering.” For Johnson, proprietor and framebuilder at […]

Haute Bicycles: Affordable Artistry

This new company from Richmond, Virginia has a wealth of experience in bikes as well as the bike biz, which shows not only in the quality and features of their bikes, but also in the way they present their offerings.

Making the Case for Pro Cycling Team Mechanics

Warning! Home mechanics may not want to read this article. And why not? Because if you’re like the PBE News Team, doing so may create a yearning satisfied only by the outlay of a pretty penny for something you can get for less money in other forms, but which won’t work nearly as well. If […]

Wan Gerin: Form Follows Function

By day, Noah Wangerin teaches design at the University of Illinois, Chicago. At nights and on weekends, he plies his passion as a builder of custom bikes that include his eponymous trade name, but which reflect the needs and desires of his clients. Rather than offering specific models of Wan Gerin bikes, Noah identifies each […]

Bassi Bikes: Bridging Rome and Tokyo (via Montreal)

Julian Gammon is the Quebecois co-owner of Bassi Bicycles, run out of C&L Cycles bicycle shop in Montreal. A bicycle mechanic for “as long as I’ve been an adult,” Gammon’s lifelong passion for bicycles involves an interesting story that undergirds the choice of a brand name for his custom bikes. When questioned about the name’s […]

Memento’s Heart Bike: an Ode to Joy

The People’s Choice award winner is a bike that captures the imagination, according to PBE founder Stephen Bilenky. Visual appeal is a big part of that, but because everyone has this circle of qualities they’re looking for, like the kind of riding it’s for, so they’re thinking they want it to have, for example, medium stays, fit a particular tire spec… they have a laundry list of physical and aesthetic attributes. The bike that encapsulates the most of what people are looking for, that bike that will win the People’s Choice award.

Silca, Where Worthy Tradition Meets Innovation

This storied Italian brand is now a US brand that’s starting to accumulate a few stories of its own, and a reputation for incorporating established cycling wisdom into new cycling tech.

Schwalbe’s Green Marathon

Schwalbe may be the greenest tire manufacturer on the market. The German company is all-in with their cradle to cradle commitment to sustainability.

Are Your Crank Arms Too Long?

Minneapolis frame builder Matt Appleman has gone deep into the subject of crank length, and he’s just not sure, but he thinks there’s a fair chance the cranks on your bike are not the optimal length for your legs. He discusses this in Seminar Room 123 on Sunday March 17 at 1:30PM.

Varlo Sports 2024 Gravel Kit (Video)

Ed Chang of the PBE Squad clothing sponsor, Varlo Sports, gives us the low-down on Varlo’s thoughtfully-designed and sourced 2024 gravelwear kit, now available from Varlo direct, and REI stores nationwide.

2024 PBExSRAMxIndustry Nine Inclusivity Scholarships

In case you missed them on our Instagram feed, meet this year’s PBE x SRAM x Industry Nine Inclusivity Scholars, whose work is on show at a special booth in the expo hall.

Velojawn

Shop Review by PBE Squad member, Miko Quisumbing As the New Year rolls on, now is a good time to get those bikes to Velojawn for some much needed TLC after a long season of riding. I recently stopped by Velojawn with some fellow PBE Squaddies and friends and experienced the newly revamped layout at […]

PBE 2021

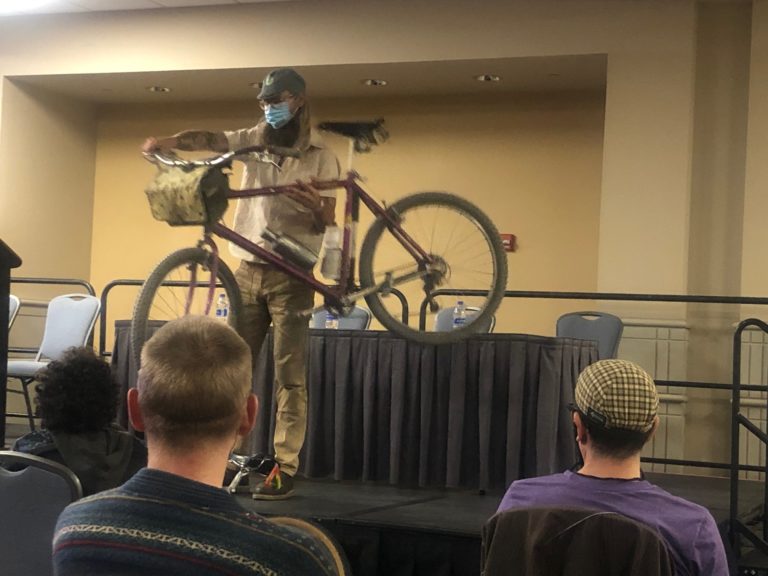

PBE Seminars offer different views on bicycle design

Every year, some of the top attractions of the Philly Bike Expo are its seminars that cover all aspects of the sport. Many of the seminars address unique or overlooked aspects of the industry, and this year’s line-up was no exception. Seminars such as “Women of the Bicycle Industry” and “Diversity and Equity in the […]

Otso Cycles/Wolf Tooth Components

Wolf Tooth and Otso Cycles are two different companies under the same ownership. Based in Minnesota, Otso offers six different bicycles, mostly all-road and gravel models made from carbon, stainless steel and titanium, along with one carbon hardtail mountain bike. Each bicycle model is also offered as a frameset, and there are options for customization. […]

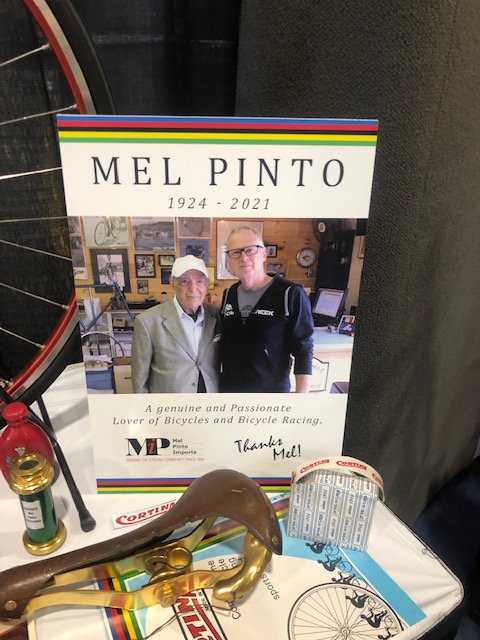

Wayne Bingham’s Mel Pinto tribute bike

The USA lost one of its chief proponents of bicycling with the passing earlier this year of Mel Pinto (1924-2021). Pinto was a Sephardic Jew whose family lived in North Africa and who spoke many different languages, including Spanish, French, Italian and English. During an encounter with American troops in Morocco during WWII while he […]

SKS/SQlab: Made in Germany

SKS and SQlab are two German companies imported to the U.S. by the same distributor, based in southern Illinois. SKS specializes in fenders and bags, while SQ Lab focuses on where the body meets the bike, namely saddles and grips/tape. Mark Burgener from SKS USA told us about the latest offerings from SKS, which recently […]

Paper Trail Bike Cafe

Bike shops that also offer baked goods, coffee or even craft beer are increasing in number these days, partly because bicycling burns so many calories and fuels demand for replenishment, but also because high-end bicycles and premium food and drink place similar demands on quality “ingredients” and attention to detail. Within this growing trend sits […]

Ignite Components: Precision Engineering

Ian Colquhoun runs Ignite Components from his home base of Allamuchy in mountainous north west central New Jersey, less than an hour’s drive from New York City but seemingly a world away. The area offers an extensive network of trails for Colquhoun to conduct some product testing on. “The Allamuchy area has hundreds of miles […]

Iozzio Cycles: special tools

Jessie Troy Iozzio makes specialized bike components for the 420-minded among us from his native Brooklyn. His mainstay product is the Shotgun, an herb chamber and spring loaded ceramic pipe intended for use in 1-1/8 steerer tubes.that offers a unique twist on the typical headset top cap ( the “Ultimate headset adjuster” his website calls […]

Tamarack Cycles: Canadian custom steel

Winters are long in Nova Scotia, Canada, but the short summers are sweet – a cyclist’s paradise with cool, crisp weather and quiet roads through lush northern countryside. Tamarack Cycles have been handbuilt in Halifax, Nova Scotia by Mark Beaver since 1990. Beaver is a 40-year veteran of the bike industry, having owned a bike […]

Tanglefoot Cycles: From the sugar shack to you

Tanglefoot is based in an off the grid sugar shack in East Poultney, Vermont. The three person operation began in 2017 and encompasses three different product lines: Tanglefoot, who produce bikes for MTB, Gravel/CX and Touring/Rando uses, Discord, who produce various components including stems and top caps from aluminum and steel, and Fifth Season, who […]

Swood Cycles: Made in Virginia

For the record, Swood Cycles are in fact made from steel, not wood. The name comes from a combination of owner Stephen Wood’s first and last names. He explains, “When I worked at a bike shop I signed all my work orders as S.Wood and eventually everyone just started calling me Swood.” Wood began operations […]

2020/2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Beth Morford

2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Meet Beth Morford. Beth is a former Olympic Sports Massage Therapist turned bike shop owner and is now adding frame builder to her resume. In 2017, she completed the Yamaguchi Frame Building School training program. She apprenticed under Julie Pedalino, and continues to turn to her for mentorship and […]

PBE Recipes: Mushroom Stroganoff (Vegan Option)

By Kathleen “Taffy” Medley Category: Anytime nourishment! Ingredients: 2 tablespoons grape seed oil, divided 1 large yellow onion 1 lb mushrooms 3 cloves of garlic, minced 2 teaspoons fresh thyme, picked 3 tablespoons flour 3 1/2 cups vegetable stock** 7 oz/200g dry egg noodles*** 1/2 cup plain almond milk Salt and pepper For garnish: Parsley […]

PBE Recipes: Morning after, (and before!)

by Rachael Sage Category: Anytime nourishment! Thoughts: I like to cook according to my refrigerator to keep things simple. Winter in Michigan requires many calories! And I like to maximize them with what I have access to. Here, I found farm fresh eggs and shaved ham from my sisters farm! Brussels sprouts and potatoes I […]

PBE Recipes: PB Energy Jawns!

by Miko Quisumbing Category: On the bike snack Thoughts: I love this recipe because it’s NO BAKE, which means more time to ride! I’m always trying to find little shortcuts that let me balance out Bike and Dad Life, and this is one of them!.I typically enjoy these between late fall to early spring since the […]

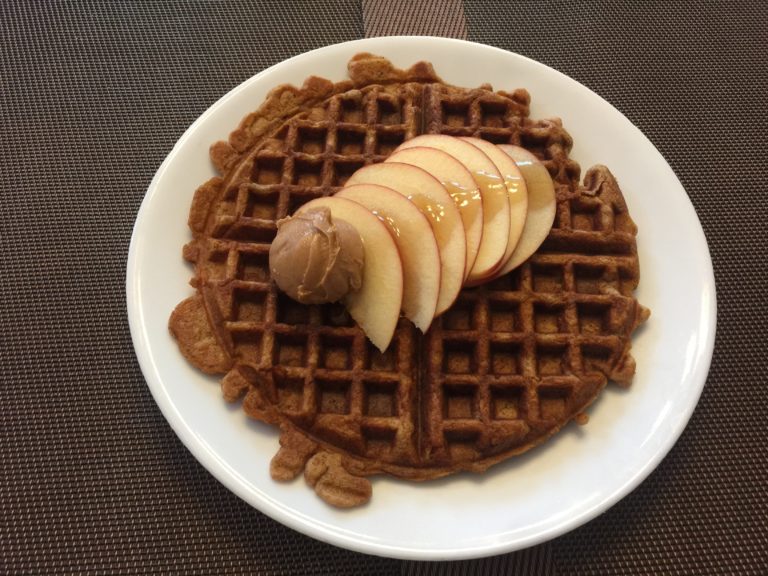

PBE Recipes: Sweet Potato Waffles

by Vanessa Romano Category: On the bike nutrition or post ride meal! Ingredients: Directions:

PBE Recipes: Mango kale Luxuroothie

by Taylor Kuyk-White Category: Anytime nourishment Ingredients:

PBE Recipes: Bright and Crunchy Carrot Slaw

by Stephanie Halamek Category: Anytime nourishment Thoughts: March is typically the toughest time of year for fresh produce- we’re nearing the end of winter vegetable season, but haven’t quite gotten to the first harvests of spring. I often find myself bored and tired of a lot of the soft, warm foods that I’ve been eating […]

2020/2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Guy Stone

This week we will be re-announcing the winners of the 2020 PBE x SRAM Inclusivity Scholarship for Framebuilders! They are the now the 2021 recipients as it has rolled over to 2021 due to there not being an event in 2020. We will be awarding the scholarship to 4 builders and will announce one at […]

PBE 2020

2020/2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Beth Morford

2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Meet Beth Morford.

Beth is a former Olympic Sports Massage Therapist turned bike shop owner and is now adding frame builder to her resume. In 2017, she completed the Yamaguchi Frame Building School training program. She apprenticed under Julie Pedalino, and continues to turn to her for mentorship and guidance. Beth leads urban WTF rides in her Eudora KS community, and hosts open shop nights at her bike shop free of charge for anyone who wants to tinker on their bikes.

“We adhere to the @wtfbikexplorers Industry Pledge at my shop and just in life in general,” says Morford. “I have the deepest passion for serving any and all womxn, adults and youth!”

We asked her what she believes receiving a PBE x SRAM Scholarship would mean to her.

“Short-term, it will help take the financial pressure off of me for my PBE build. Framebuilding is not a cheap hobby or career to have, as all builders understand. I already own a brick and mortar bike shop, which is difficult enough to keep open on its own,” she says. “Long-term, this scholarship will help me develop newer and stronger relationships within the industry that I may not have developed otherwise, which is invaluable in and of itself.”

Congratulations Beth! Looking forward to seeing you in Philly! #phillybikeexpo #pbe2020 #pbexsraminclusivityscholarship

Save the Rim Brake! A Reactor Dream Build

Every now and again we get a chance to work on a bike that perfectly aligns a rider’s vision and our own, and this very special Reactor for No. 22 dealer Larry Marcus is our latest example of that alignment.

Starting with our aggressive Reactor frame with custom geometry, the goal was a responsive, enduring build highlighting that in many ways rim brakes are still on the very cutting edge of road race performance.

The Reactor platform was the perfect start for this project. It’s not the lightest frame available, but the extra grams budget in the frame allow for outstanding responsiveness, ride quality and durability. The Reactor’s enormous chainstays and large, aggressively butted main tubes give it a rock solid ride under hard efforts, with careful tuning keeping just enough of titanium’s legendary ride quality to make the bike a welcome companion on long rides.

Marcus’ goal was to focus on ride quality for the frame, and aggressively trim grams everywhere else. To that end, the build is dripping with exotic parts aimed at shedding grams and saving watts. Lightweight’s Meilenstein Obermayer wheels feature a deep profile and an otherworldly weight of just 935g for the pair. THM’s Clavicula cranks, Ulna handlebars and Fibula brakes trim substantial weight compared to more “pedestrian” parts, with the complete set of Fibula brakes weighing less than a single Dura-Ace caliper.

Eager to sweat the details, Marcus’ build left no stone unturned in the quest for light weight and sharp performance. Berk’s Lupina saddle features carbon layup work suitable for a museum piece and the full carbon construction comes in at just 79g. In the drivetrain, Shimano’s faultless Dura Ace Di2 components are helped with a complement of CeramicSpeed parts, including bottom bracket, headset and most notably CeramicSpeed’s ultralight and ultra-efficient 3D printed titanium derailleur pulley wheels. PYC’s lightweight SP1101 chain looks great in black and sheds additional grams.

All of the lightweight componentry added up to an as-pictured weight of just 12.78lbs (5.8kg) for this Reactor.

Wrapping the entire package together is a one-of-a-kind finish that mixes our in-house anodizing with Cerakote done by Black Magic of Portland, OR. Cerakote is a finish that we are particularly excited to use. It is a unique ceramic coating that is both extremely durable and impossibly thin, which complements our similarly thin anodized finish beautifully while offering a range of colours and tones not achievable by anodizing. The end result is a finish that shows off the beauty and lustre of titanium while maintaining the material’s legendary durability.

For Marcus, the sum of all of these details is a razor sharp build that shows that rim brakes are still deserving of recognition at the very sharpest end of the road bike spectrum.

2020/2021 PBE x SRAM Inclusivity Scholarship for Framebuilders: Guy Stone

This week we will be re-announcing the winners of the 2020 PBE x SRAM Inclusivity Scholarship for Framebuilders! They are the now the 2021 recipients as it has rolled over to 2021 due to there not being an event in 2020. We will be awarding the scholarship to 4 builders and will announce one at a time so you can get to know them and so they receive the recognition they deserve! Meet Guy Stone, 2021 Awardee of the Philly Bike Expo Framebuilder Scholarship. After attending a BREW Racing frames TIG class in May 2015, and then a brazing class from Joe Bringheli in 2016, Guy began building frames in his home shop. For the past four years he has averaged about ten brazed steel frames per year. They range from rando and road to mountain, fat, tandem and youth bikes.

Guy Stone is very involved in his local Cincinnati, OH mountain biking community, providing volunteer accounting services to the board of the Cincinnati Off Road Association (CORA) including filing the organization’s tax returns, consulting and audit support. Guy and his wife also started a small private foundation, Relstone Charitable Trust. Through the foundation, the Stones have made donations directly to local trail stewards in order to support trail maintenance and expansion in the CORA system.

“I have a lifelong passion for cycling,” says Stone “I (also) have the deepest passion for serving veterans and those that have suffered traumatic injury. Two-wheeled therapy is a positive outlet to promote healing and coping with injuries (mental, spiritual & physical).” Stone looks to the future in which he can build a complete bike every year free of charge for a veteran or other individual who has suffered from a traumatic injury.

Stone tells us that his short-term career plan is offering awesome custom bicycles to the relatively small Cincinnati, OH market.

“I don’t fear failing,” says Stone. “I actually embrace it. I learn for my mistakes and move on to learn from new mistakes. With each project I try something new to keep the learning curve high.”

His long-term career goal is to acquire a larger shop with machine tools. Similar to his mentor Joe Bringheli, Stone would like to offer frame building tools and supplies in addition to bicycles.

“I hope that seeing an African American male participate in the Philly Bike Expo will inspire other people of color.”

Congratulations, Guy! Looking forward to seeing you in Philly!

In 2019, the Philly Bike Expo announced a new framebuilder scholarship program, sponsored by SRAM. The PBE Inclusivity Scholarship supports women, trans, and POC framebuilders who have been underrepresented at bike shows and in the industry at large. .Scholarship recipients will receive co-operative booth space at the 2020 Philly Bike Expo, travel, accommodations and shipping for the Expo as well as a complete SRAM build for their show bike! #phillybikeexpo #pbe2021 #pbexsraminclusivityscholarship

“Missing” Events

Witten by Alex Felmeister

Photos by Jason Giordano

Being on the Philly Bike Expo Squad this year, I fully expected to step up my participation in cycling events in 2020. Like everyone else, I am pretty disappointed my regular events, clubs rides, and planned new adventures have been postponed or canceled. One particular event, extra close to my heart, is the Eagles Autism Challenge. This event is a new event only its third year and includes 50, 30, and 15 mile rides, a 5k race and a sensory walk. No matter how you participate, you end your ride, run, or walk at a huge finish line party on the field of Lincoln Financial Stadium. It’s not just a great 50 mile ride for me, but it is a magical event that is uniquely Philadelphia; when you see this diverse city come together for one cause in a beautiful way around our beloved Eagles. I selfishly anticipate the reveal of the cycling jersey for the ride. If you pledge and raise enough money, you get one of three special limited-edition jerseys based on your fundraising goals from Primal, a Philly Bike Expo exhibitor! This year I blew away my fundraising goal raising over $5,000, so I was really looking forward to this year’s ride to represent this accomplishment in an All-Pro Plus Jersey from the Eagles. Riding and running for charity is a great way to engage in your sport and feel like you are making a difference. I personally like events that have local impact, so this one has become one of my favorites. Philanthropy is one of the only ways to make a substantial impact and raise awareness for complex issues like autism.

I ride for Team CHOP. The Children’s Hospital of Philadelphia (fondly known locally as CHOP) cares for more than 10,000 patients with autism each year in almost every clinical area, and teams from CHOP’s Center for Autism Research and Autism Integrated Care Program include rehabilitation therapists, developmental pediatricians, neurologists, psychologists, geneticists, psychiatrists, advance practice nurses, social workers and many others. These folks have led breakthroughs for children and families, from making earlier diagnosis possible to improving therapies and access to services. It is an honor to ride for them and raise money for them.

In 2019, the Eagles Autism Challenge funded competitive research at The Children’s Hospital of Philadelphia (CHOP), The University of Pennsylvania, and Thomas Jefferson University. They have also awarded two post doctoral fellowships; one at CHOP and one at Temple University, and this means that two new scientists are getting their research funded here in Philadelphia at their respective institutions. This type of direct impact on the local research community means access to opportunity for new researchers and for much needed attention brought to this issue that affects so many local families. The Eagles Autism Foundation has also funded programs through community grants that directly impact Philadelphia communities. This organization has also engaged participants and fundraisers in generous ways. I had the opportunity last year to attend the recent Eagles/Dallas game and see first-hand the generosity of fans and prominence of this foundation throughout the game thanks to tickets I won at the Philly Bike Expo last year!

Yesterday, Saturday May 16th, would have been the ride. I put on my Primal jersey and hit the roads in honor of cycling and the cause this event supports.

Go Team CHOP! Go Birds!

PS: A special heart-felt shout out to families at home taking care of their kids and loved ones affected by autism during this time of isolation. I ride and raise money for you.

Riding Solo: Mental Toughness and Incremental Landmarks

By Mark Yanagisawa

During these times of uncertainty around the world, one thing has been my rock through it all – still being able and allowed to ride for exercise – of course while staying socially distant. As my work has moved from the office to my living room, the normal routine is not so “normal”. I have to make the mental switch from work to “not-work” at the end of the day. Also with most events and rides cancelled for the foreseeable future, motivation to train towards a goal might be hard.

I’ve found my motivation in riding to exploring new places, discovering new bakeries, re-visiting favorite roads and pedaling familiar routes. All of this, solo; alone; self-supported; me and my thoughts; me and my machine.

Riding solo can be a daunting task, but the more and more that I do it, the more I enjoy my time on the saddle. I find peace and joy in it. While it might appear that I jumped straight into the deep-end taking-on centuries, its quite the opposite. I started out riding 20 miles solo, then 40, then 70 and more. I had to build my mental (and physical) strength to be on the bike for more than 2 hours at a time, working my way up to 5 hour plus rides. I rode familiar routes that I did on group rides before using Strava and Garmin to map out longer adventures.

Whether its your first ride or 100th solo ride, here are some tips to prepare and ride solo.

1. Be Seen.

Safety is my number one priority and staying visible is the most important! Wear a bright kit and helmet with reflective bits. Run a blinking tail light and a low beam headlight.

2. Route.

Keep it close – for your first solo ride, stick to a route that you know and are familiar with – like a weekly group ride route – the one you know like the back of your hand. This is a great way to keep your mind stimulated on reaching the next landmark. For example, “the next turn is at the CVS, then up the winding hill, around the bend, back down to the trail, then take the trail home!” With this mental trick, you’re breaking down the route into small, manageable goals, check-points, and incremental landmarks. This helps clear the “miles” and “hours” from your head.

As you become more confident – start your route on roads you normally take, then venture beyond the turn-around point. Plan a new destination and ride! This can be an extra 5 miles beyond. On the return trip, connect to the same roads that you are familiar with. With this mindset, when I come into the river trail – 12 miles from the city- I am mentally thinking, “I am close to home”.

If you’re still following along – I’ll be the first to agree that the same roads might get boring, BUT that is a good sign because this is all to build your mental toughness for riding solo. When my mind switched from “miles left” to “land-markers” that’s when the beauty started.

Venture in a new direction – Pick a new direction or destination to travel to – plan a ride to a bakery, brewery or bike shop that is along the route to get yourself looking forward to that croissant, beer or snack! If possible, incorporate familiar roads into the route on the return trip – again in the theme of looking forward to landmarks. Start small and then increase your mileage as appropriate!

The world is your oyster – once you get the mental and physical toughness to ride solo, whatever distance, take to the road and explore the world from your doorstep!

3. Route Planning

I use Garmin Connect and Strava Routes to plan most of my routes. To my limited understanding, they use heat mapping to create routes and I have not been disappointed in their algorithms to route me on safe roads, bike paths, or trails. As the miles increase, I make it priority to find “rest-stops” to fill water and re-supply if needed – I typically plan for a stop every 30 miles. Garmin and Strava routes both interface nicely with my Garmin head unit.

4. GPS Unit.

A GPS unit, like Garmin, Wahoo, or Hammerhead can be very useful tool to plan and navigate routes, track metrics (HR, power, cadence, speed, elevation, mileage, time). I also have the Garmin Livetrack and Strava Beacon for my family to track me when I am riding to make sure my dot is moving and for safety (see #1). I personally love my Garmin Edge 530 and the functionality it provides me.

5. Dressing for the Weather

When riding solo, look up the weather forecast and make sure that you’re prepared for the weather. Layering is key. Clothing with zippers is a plus so you can zip and unzip, layers for perfect temperature regulation. For example, during climbs your blood will be pumping and body will warm up, so unzip the layers and let your body breathe; and on the downhills protect yourself from the breeze and drag and zip all of your layers. From the base layers, arm & leg warmers, bibs, jersey, vests, and thermal long sleeves – there can be many combinations that will get you suited to be prepared and cozy for the weather.

6. Drink and Nutrition

Make sure that you have enough (or more than enough) liquids and nutrition with you when you are riding – and more so when you are riding solo because you don’t have buddy to share water with (see CDC on sharing and social distancing). Water with Skratch or Nuun helps replenish what you sweat, and nutrition like Honey-stinger Gels or Cliff Bars provide much needed fuel to keep you moving. I like to drink every 5 miles and eat 100-200 calories every 15 miles – your mileage may vary, but make sure you are doing this and are prepared. Also, bring money so you’re ready for a rest stop fill up.

7. Spares

When riding solo, you should be prepared for most situations you’ll encounter. This was the most daunting part to me but being prepared helped ease my anxieties! A tube, patch kit, tire lever, pump or C02, and tool are essential for riding solo. If you’re planning a longer ride, a charger, additional tube and spares might be useful. Real story, on a 160 mile trip (Philly to Lancaster), I flatted twice – I was prepared with two spare tubes and a hand pump, so it did not halt my ride.

8. Other accessories to keep you rolling

While not essential to riding solo, I have found a few accessories to help me go further, more confident and comfortable on my bike…

Hunt Superdura Dynamo (SON 28) Wheelset – I generate my own power. Hunt’s pre-configured wheelset makes the plunge into dynamo EASY – they spec a high quality SON 28 hub, laced to their asymmetric rim and are able to be configured to tubeless/tubed and rear cassette hub.

Sinewave Beacon – This takes the power I create and makes it into USABLE electricity! It simplifies the electronics to a single unit that is a light and charger all in one. I can confidently ride without worrying if my light is charged. I have used it to also charge my Garmin, phone and portable battery.

WTB Exposure 34’s – With plenty of rubber and volume beneath me, I can take on paved and unpaved roads confidently and equally, all while maintaining comfort. The Exposure line-up has a smooth center tread for fast pavement section and small side knobs to grip dirt or gravel, providing me confidence for traction.

Lupine Rotlicht – “Isn’t just a tail light?” No, its not just a normal light. It is a super bright (>160 lumens), long lasting (>30 hrs), compact light with a built in sensor that goes solid when braking (like a normal car would).

The key takeaways are to be safe, be seen and be prepared. And with some metal preparedness, you can build some mental resilience to endure riding solo.

Rubber Down. Head Up.

Mark

2020 PBE x SRAM Inclusivity Scholarship for Framebuilders

*Applications are now open!*

In 2019, the Philly Bike Expo announced a new framebuilder scholarship program, sponsored by SRAM. The PBE Inclusivity Scholarship supports women, trans, and POC framebuilders who have been underrepresented at bike shows and in the industry at large.

Scholarship recipients will receive co-operative booth space at the 2020 Philly Bike Expo, travel, accommodations and shipping for the Expo as well as a complete SRAM build for their show bike!

We are now accepting applications for the 2020 Philly Bike Expo Inclusivity Scholarship. 4 recipients will be selected. Application deadline is April 30th and recipients announced on May 28th. Apply here: (You will need to sign in to google to apply due to file upload required.) #phillybikeexpo #pbe2020 #pbexsraminclusivityscholarship

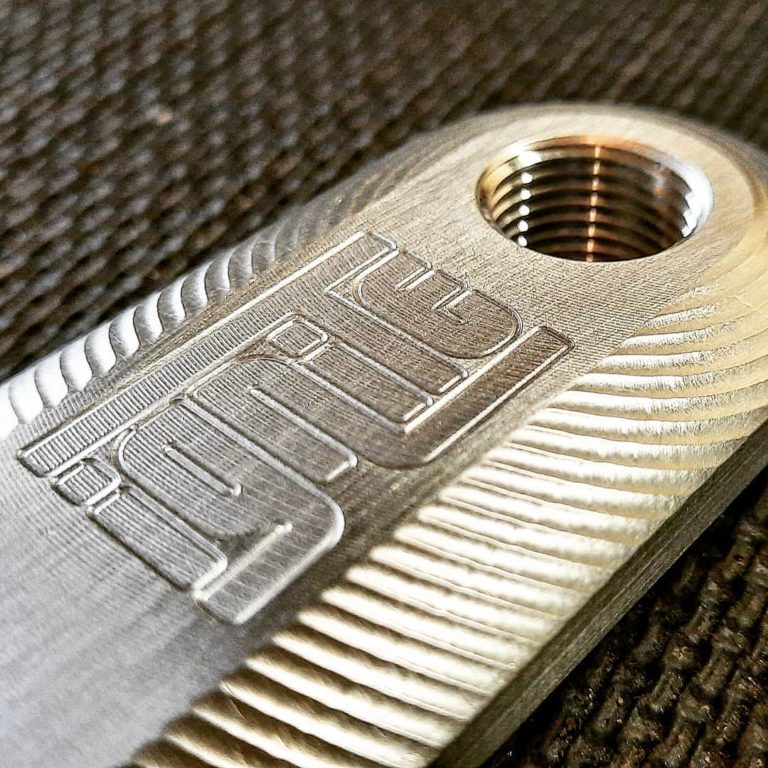

Titanium Finishing Co: Pretty Parts

Titanium alloy is an important metal for the bicycle industry. If you aren’t riding a frame made from it, you probably have some titanium bits somewhere on your bicycle. But there are few companies who can survive producing titanium parts for the cycling industry alone. Luckily, there are a number of other industries – aerospace and medical among them – that use titanium components, so with a diversified clientele, titanium finishing becomes a profitable industry.

Melinda Cunningham is Vice President of Titanium Finishing Company, who apply finishes to titanium components for a number of industries. The company was started in 1970 by her grandfather, Melvin Faul, and is located in East Greenville, Penn., just south of Allentown. As an avid cyclist, she joined the family business with her husband, Eddie, also a cyclist, who works as a Senior Metal Finisher at the 15-employee company. So, it was only natural that custom bicycle parts and finishes would be added to Titanium Finishing’s list of specialties.

Melinda explains: “Titanium Finishing Company specializes in anodizing titanium, hard anodize of aluminum, and application of Cerakote products. With a combination of these finishes, or even on their own, they’re great for customizing bike frames and components. TFC also offers in house graphic design services, so the options for customization are almost limitless within the capabilities of coatings we offer.”

Before officially joining the family business after a stint at Penn State, Melinda grew up around titanium finishing, so she knew the ins and outs of the process. But husband Eddie came to the business from a different background. For over ten years he was a tattoo artist. The couple’s penchant for creativity finds an outlet at TFC.

“Both of us enjoy exercising our creative side, especially on bike themed projects because it gives us a chance to mix business with our passion for riding! We love having the chance to interact with like-minded individuals who want to customize their frames and components,” says Melinda.

While for some, the raw beauty of unfinished or lightly brushed titanium, resistant to rust and corrosion, is desirable, Titanium Finishing Company allows bike fans to get creative and even wild with their finish concepts (think of intricate tattoo designs). The in-house graphics team and Eddie on the production side of things will turn your dreams into bespoke beauty!

Arko Bici: Beautiful Process

The nation of Slovakia in central Europe may not come up often in general conversation this side of the Atlantic, but if you inhabit the cycling world, you’re likely to know something about three-time World Road Race Champion Peter Sagan, who hails from Slovakia. The eastern half of the former Czechoslovakia, sandwiched between Poland to the north, and Hungary to the south, is experiencing a cycling boom, thanks in part to Sagan.

Slovakia also doesn’t usually cross the mind when thinking of custom framebuilders, but Marek Parajka of Arko Bici might lift the profile of bicycle fabrication in Slovakia the same way Peter Sagan lifted it for cycling in general. The one man operation produces attention-getting custom steel frames and stems with exquisite detail and beauty. Parajka is coming to the Philly Bike Expo in November to introduce himself to the U.S. scene. It’s likely that he’ll make a big and favorable impression.

Parajka is a certified welder and metalwork technologist who together with his wife bought an old mill – water wheel and all – in the village of Hradiste pod Vratnom in western Slovakia. It serves as both their home and frame workshop. The name of the brand, Arko Bici, comes from Parajka’s dog, Arko, and Bici, the Italian word for bicycle. Parajka began operations in 2009.

Every Arko Bici frame is handcrafted using steel tubes of the client’s choice, and frames can be lugged or fillet brazed. Parajka builds frames for road, randonneur and cyclocross/gravel uses. He does all of his own painting as well, and eschews the powder coat trend – wet paint only for every Arko Bici.

Asked about his favorite part of his work as a framebuilder, Parajka said that he enjoys the three “B”s of framebuilding: brazing, brushing, and buffing, but he also really enjoys taking quality photos of his finished frames and bikes, which can be seen at his Flickr account. All frames are built to order for his customers, who come from all over Europe and soon, he hopes, from the U.S. as well.

Parajka clearly sees framebuilding as an art form – a craft in which his customers also play a role. “Framebuilding is a lifelong craft,” he says. “It’s a beautiful process and the client himself is a big part of it. He brings his ideas and perhaps dreams of what the bike is going to be like, and I bring them to life.”

As cosmopolitan as his customer base may be, Parajka has a strong commitment to sourcing local supply chains and lifting the local economy of western Slovakia. “When you consider hand made steel frames, you don’t pay only for this unique piece, but you also support the local supply chain. Tubes come from Italy or UK. Welding material, gasses, brazing rods, tools, paints, and energy I pay for. It all comes from local or EU suppliers.”

Jersey Bents: Recumbent by Choice

The prevailing narrative is that recumbent bicycle riders are a breed apart, never having ridden regular diamond-framed bikes, and only able to see things from their viewpoint – lower to the ground as it is.

Larry Hobbs, owner of Jersey Bents bike shop in Hamilton Square, New Jersey, rewrote this script. As with many things in life, happenstance brought him from being an avid rider of a regular bicycle to owning a recumbent-only bike shop.

Hobbs writes at the Jersey Bents website: “I have ridden a diamond frame for more than half of my life. Rides as short as a few loops around the neighborhood or 100 miles. I was “forced” into the recumbent community after a fall left me with a lingering elbow injury. BEST THING to ever happen to me!”

Five years after his recumbent conversion, Hobbs had the opportunity to purchase an existing bike shop (not specializing in recumbents), and he realized his dreams of opening his own business. The rest, as they say, is history.

Hobbs’ son Matt is co-owner, head mechanic, bike builder and caretaker of the shop dog, Bacon. Unlike his father, Matt wasn’t forced into a recumbent, but a fascination with his father’s recumbent bike led to a lifelong interest in the mechanical side of recumbents.

“My dad’s first recumbent, a long wheel base Gold Rush, intrigued me like nothing has since I first saw a snowboard! When he brought that bike home, I was fascinated by it. I learned to ride the recumbent and it opened my eyes to a whole new world!” he says.

Jersey Bents has the largest selection of recumbent bikes and trikes for sale in the tri-state region. They serve as a clearinghouse for information and support for all things recumbent, and offer free test rides and bike fitting.

Recumbent bikes from Alinker, Azub, Bacchetta, Catrike, Cruzbike, Day 6, ICE, Lightning Cycle Dynamics, TerraTrike, and Trident Trikes line the racks in the shop, and they offer a wide range of accessories and expert repairs to get you on the road on a recumbent and keep you pedaling.

Jersey Bents is open three days a week, but are available other times by appointment. Larry and Matt advise that it’s best for customers to call ahead to the shop in any case, so that they can prepare appropriate bikes for test rides. They also encourage customers to come wearing appropriate cycling attire and shoes, to get the best performance out of the test rides.

Although Jersey Bents helps a lot of cyclists who are forced into riding recumbents because of injury, there are a growing number of cyclists who choose to ride recumbents for the pain free miles that they promise. Whatever your reasons for riding a recumbent, they hope to serve your needs soon.

Iride Italian Bicycles: Classico!

Let’s set the record straight: Italian builder Iride Italian Bicycles didn’t enter the U.S. market ten years ago with a cute, media friendly name (as in “I ride”) to help people remember them. But if this particular mnemonic works for you, that’s ok too.

“Iride” (pronounced EAR-ee-day) is the Italian word for “iris”, and it also refers to the colors of the rainbow, the visible spectrum, so it’s even more of an appropriate name for a bicycle brand in this context. Cicli Iride was established in 1919 by Umberto Gemmati in the Veneto region of northeastern Italy. Today, Umberto’s grandson Carlo holds down the fort at the House of Gemmati.

Classic handbuilt construction with Columbus Niobium SL steel tubing brazed to investment-cast lugs reflects the focus on tradition at Iride. Even the classic-but-compulsory Ferrari red paint scheme on every Iride model – an Italian version of Henry Ford’s famous “any color you want as long as it’s black” directive – sings che bello.

Iride has a racing pedigree on both the track and the road, and they offer the Nucleo road racing model, and the Pista Fixed for the velodrome. But it’s with a couple of different models that Iride really stands out from the sea of Italian builders (even those still building with steel tubes).

The Il Mercante has a 20-speed drivetrain and is intended for urban cycling. It offers an upright yet still aerodynamic position for the rider courtesy of Gipiemme Piega Sport Torino “pull back” handlebars. Keeping with Iride’s neo-retro vibe, the Mercante offers an antipasto platter of components from various Italian manufacturers, similar to how manufacturers sourced parts from many different companies during the 1970s and 80s, before the proprietary groupset began to rule the roost.

The Monello is the single speed version of Il Mercante, and the Mixte offers step-through geometry with the same single speed drivetrain. All of Iride’s models offer a full-range of custom options, including frame geometry, the use of oversize steel tubing (on some models) for a stiffer ride, chrome lugs and trim, water bottle mounts, saddle and seatpost choices. Forks come in three options: a full carbon Columbus Minimal fork (which Iride recommends), a carbon fork with steel steerer, or a full steel fork made of Columbus tubing. You can also choose your wheelset, upgrade to a Chris King headset, and have your name hand painted under the clearcoat.

Iride offers these options on a full bike build that still comes in at a lesser price point than going full custom. While all of the options are subject to upcharges, there really is no limit to how much you can customize your dream bike.

As long as you love red.

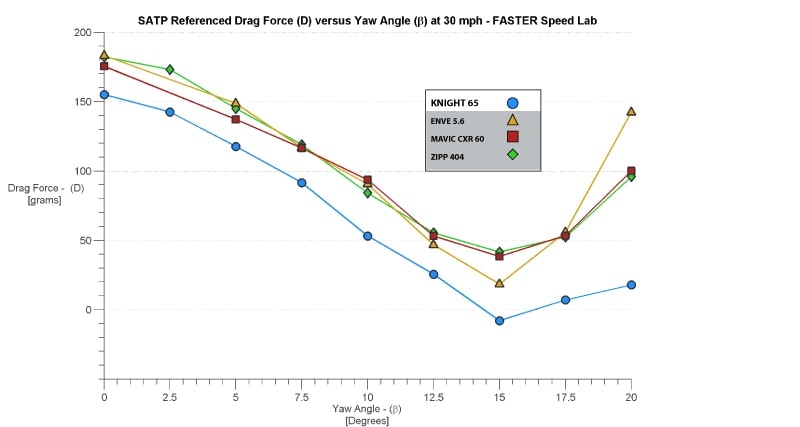

Knight Composites: Fast Company

Boulder-based Knight Composites makes wheelsets for the road, the trail and the cyclocross/gravel circuit. Knight wants you to ride long, ride hard and ride fast, and their carefully engineered and crafted wheels will enable this for you.

Knight makes carbon and alloy wheels in 700c, 27.5” and 29” sizes for road, triathlon, MTB and cyclocross/gravel uses. The rims come in five different depth profiles (25 – alloy only, 35, 50, 65 and 95 mm), plus a full carbon disc wheel, and they are made in versions for clincher, tubeless clincher and tubular tires. The wheelsets also come in both rim brake and disc brake iterations. Adding further to the choices available are either proprietary Knight hubs, or versions from Chris King or DT Swiss, and with cassette compatibility for Shimano/SRAM, SRAM XD or Campagnolo.

With all these choices for the consumer, Knight is clearly committed to meeting the full needs of the marketplace, but they see their advantages focused in three areas critical for cycling performance: speed, compliance (comfort), and durability. For each of these salient factors, Knight has engineered unique solutions that benefit the rider.

Speed is enabled through the use of Computational Fluid Dynamics (CFD) to develop Knight’s proprietary Trailing Edge Aerodynamic Manipulation (T.E.A.M.) rim profiles. The T.E.A.M. technology maximizes airflow around the rim, tire and downtube, minimizing drag-inducing losses and actually providing power-saving lift.

For compliance or comfort, Knight uses an EPS manufacturing process to control uniformity and compaction in the carbon rim layup. This avoids the need to overbuild the rim, which can cause a harsh, overly stiff ride. The result is a balanced, laterally stiff, yet vertically compliant ride that is as comfortable as it is efficient.

All these advantages of speed and comfort mean nothing if your wheels fail on you, so for durability, Knight also relies on the carefully-engineered EPS carbon layup process. The precision of EPS molding allows Knight to reduce “carbon drift” and “voids” associated with bladder-only molding, which can cause weak spots. Tests have proven Knight’s wheelsets to be 30% more impact resistant than their competitors.

Knight Composites’ speed, comfort and durability advantages make their wheels an excellent choice for racers in a number of different disciplines. Add to the list a lifetime crash replacement policy and lifetime warranty, and Knight fully suits the needs of those who prowl the racing circuit, or for any cyclist who values performance and durability.

Product Manager Brad Swaim hinted that the company will expand their product offerings beyond wheels, but was non-committal before we went to press. Watch this space for more news, or better yet, come visit Knight Composites’ booth at the Expo this November to see their 2020 introductions!

Frontier Bikes: Very Sassy!

Frontier Bikes is a woman-owned cycling emporium that offers handmade steel bikes, a full-service bike shop featuring expert repairs, and a spin studio all under one roof in Eudora, Kansas, 30 minutes west of Kansas City. Located in the heart of Kansas gravel country, Frontier supports group gravel and MTB rides, as well as local Eudora High School’s Cardinals Cycling Club.

All of this craft, service and advocacy comes with a good bit of irreverence and humor, sassy customer service, and Frontier’s trademark “100K Mansplain Fee”.

Before following her passion for all things two-wheeled, Frontier owner Beth Morford ran a successful sports massage practice. “I traveled with Division 1 universities and Team USA. My biggest career achievement with that was being selected to be on the 2016 Summer Olympics medical staff in Rio de Janeiro,” she says.

Morford honed her bicycle skills by working as a shop mechanic for three years, and then by enrolling at Japanese-American framebuilder Koichi Yamaguchi’s School of Framebuilding in Colorado, which she graduated from in 2017.

You can have a bespoke steel frameset (specializing in smaller riders) built for you by Morford, but Frontier also offers custom wheel builds, expert repairs and a variety of bicycles and accessories from brands like Marin, All-City, Surly and many others.

Frontier is the kind of place you can hang out before or after your ride over some of Kansas’ best gravel roads. Morford says,“We have loads of gravel roads and loads of gravel races in Kansas! We’re sort of the mecca, actually!” And just 3 hours’ drive away is the trail network of Bentonville, Arkansas, which Morford rates as her favorite cycling destination.

If you’re wondering about the name, well yes, “Frontier” evokes the spirit of the American west, but it also reflects Morford’s love of all things Star Trek (space…the final frontier). “I’m sort of a Trekkie at heart,” she admits. The shop jersey also embodies this star-dappled theme.

More than anything else, Frontier Bikes wants to sell you on the love of cycling, and there’s nothing sweeter for Morford than spending hours working on a new build, taking it from concept to finished product and then having it really come to life under the legs of its new owner.

“I love seeing the finished product, getting to ride it, or seeing someone else take it home and love it!,” she says.

PBE 2019

Cinelli USA: Tradition Reinvented

If you’ve been around cycling for 30 plus years like me, then you know the Cinelli brand as one of the stalwarts of the industry. Back in the 1980s when I cut my teeth as a junior racer, Cinelli handlebars and stems, with their proprietary 26.4mm clamp diameter, were standard equipment for racing cyclists. Cinelli Supercorsa framesets, in striking cobalt blue and Ferrari red paint schemes accented with chrome lugs, were coveted for their high aesthetics and performance, and to this day they command premium resale prices.

Traditionalists will rejoice at the news that you can still purchase the venerable Cinelli 1A stem at the Cinelli USA website, along with the Model 64 shallow drop handlebars and the old Model 65 “criterium” bars, mine and Roger De Vlaeminck’s personal favorites. But beyond these legacy components, the Cinelli line has expanded greatly in scope and depth, all of it for the better.

First, a quick history of the brand. Cino Cinelli was an Italian road racer active during the WWII era. He won the Giro di Lombardia in 1938 and Milan-San Remo in 1943. After suffering numerous mechanical breakdowns in races, Cino started producing bars and stems with his brother Giotto in Florence in 1948. Eventually the brothers moved the company to the heart of Italian industry, art and fashion, Milan. In 1978, Antonio Colombo of the Columbus tubing company, became president of Cinelli, and the company was eventually folded into the parent company, Gruppo S.r.l., in 1997. Like many Italian companies, it’s still run like a family business.

Also like many Italian companies, production of some entry-level products has moved to Asia, but characteristic Cinelli artistic flair and performance-minded design still infuse the product line. Case in point is the Vigorelli steel track frameset, a lower-priced cousin of the well-heeled and Italian-built Supercorsa Pista frameset, named after Milan’s iconic Vigorelli velodrome and constructed from Columbus Thron tubing. A working-man’s track frameset, the Vigorelli performs well on banked turns as well as Red Hook-style fixed-gear criteriums, thanks to design input from Team Cinelli Chrome, 2015 Red Hook series champions.

Cinelli also offers complete bikes for road, track and the increasingly popular adventure bike category. The Zydeco “full-color” is a disc-brake equipped gravel/adventure bike with an aluminum frame made of Columbus Zonal and striking, multi-color graphics and paint. The Zydeco comes with a mix of SRAM Apex, FSA and Tektro parts with, of course, a Cinelli cockpit.

The aforementioned classic handlebars and 1A stem are accompanied by newer offerings made of both aluminum and carbon fiber with modern 31.8mm clamp diameters. For the ultimate in strength, stiffness and control, the Cinelli Ram 3 carbon fiber integrated bar/stem combo comes with ergonomic design that includes the “Thumb Zone” – a surface recess for resting thumbs. The cable routing is integrated into a cycle computer holder bridge, The Manta Deck, that significantly improves braking and shifting. Progressive Parabolic Action (PPA) shaping allows a perfect hand grip anywhere on the bars.

Any discussion of Cinelli wouldn’t be complete without mentioning the classic finishing touches the company is famous for, including the well-regarded cork ribbon handlebar tape which, upon its release in the 1980s, has launched a thousand imitators. Classic cork handlebar tape is still available in its stalwart hues (including natural cork), but has been joined in the lineup by Volee ribbon, which is synthetic and similar to tennis racquet grip tape, and colored in edgy patterns and hues.